Danish restaurant Noma, which was named the world’s best for four of the last five years, got a bit of bad news on Monday. The René Redzepi-helmed kitchen once again lost the top spot on Monday to the same competitor that beat it out in 2013: Spain’s El Celler de Can Roca.

Noma has been scrapping to keep the top spot on “The World’s 50 Best Restaurants” list for several years—it held the title from 2010 to ’12, lost it to El Celler in ’13 when it came in second, and took it back in last year. Now Noma is in third place, with an Italian restaurant, Osteria Franciscana, taking second.

The list, sponsored by S.Pellegrino and Acqua Panna, names restaurants from 21 countries. Six American restaurants made the cut, led by New York’s Eleven Madison Park at No. 5. New York State’s Blue Hill at Stone Barns makes the list for the first time at No. 49. Another first: two Asian restaurants have cracked the top 10: Bangkok’s Gaggan and Tokyo’s Narisawa.

El Celler de Can Roca is the product of the three Roca brothers: head chef Joan, pastry chef Jordi and sommelier Josep. The 55-seat restaurant in Girona features contemporary Catalan cuisine.

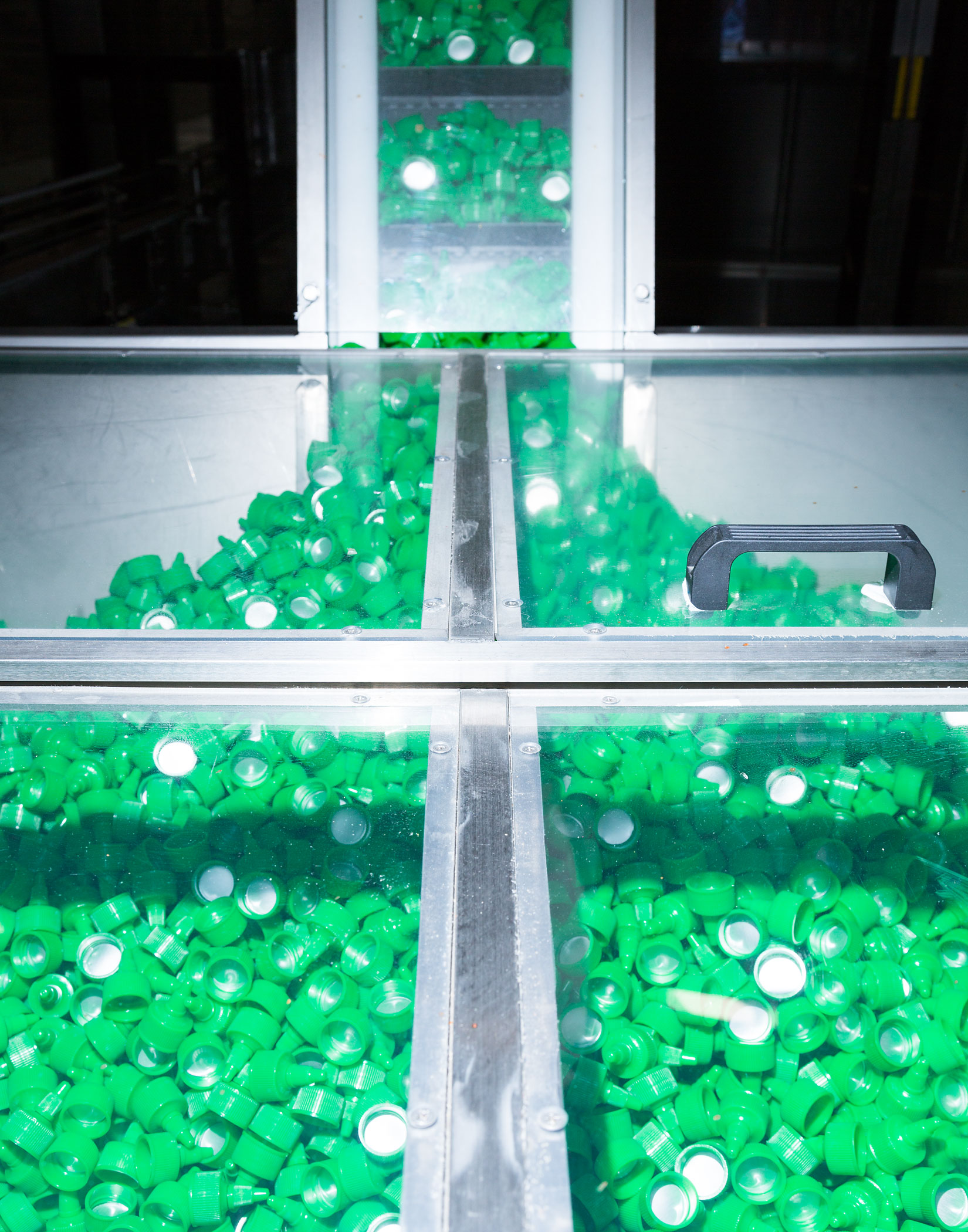

Photos: An Inside Look at a Sriracha Factory

More Must-Reads from TIME

- Why Trump’s Message Worked on Latino Men

- What Trump’s Win Could Mean for Housing

- The 100 Must-Read Books of 2024

- Sleep Doctors Share the 1 Tip That’s Changed Their Lives

- Column: Let’s Bring Back Romance

- What It’s Like to Have Long COVID As a Kid

- FX’s Say Nothing Is the Must-Watch Political Thriller of 2024

- Merle Bombardieri Is Helping People Make the Baby Decision

Contact us at letters@time.com