Sriracha-mango and chipotle-pineapple are two of the newest Chobani flavors.

They are the latest products in the brand’s “flip” series, which comes with yogurt and toppings. The sriracha-mango combo is low-fat mango yogurt with “sriracha-coated rice crisps, mini sesame sticks, and roasted and salted cashew pieces,” while the chipotle-pineapple one includes low-fat pineapple yogurt with chipotle-flavored granola, “smoked almonds, and pumpkin seeds.”

The sriracha kind is the latest novelty in the culture of unusual, sriracha-flavored food items, from Pringles to hummus to candy canes.

Some even see the new flavors as a way to spice up the market amid slowing Greek yogurt sales, as the Wall Street Journal reported in May 2015 that “Chobani’s share of Greek yogurt sales in the U.S. is down nearly 15 percentage points to 44% from its peak in January 2012.” A Chobani spokesperson says the company’s market share trend of Greek yogurt “continues to grow,” as well as sales, which, in terms of dollar sales, have “grown” 11% year-over-year and were up 18% in November.

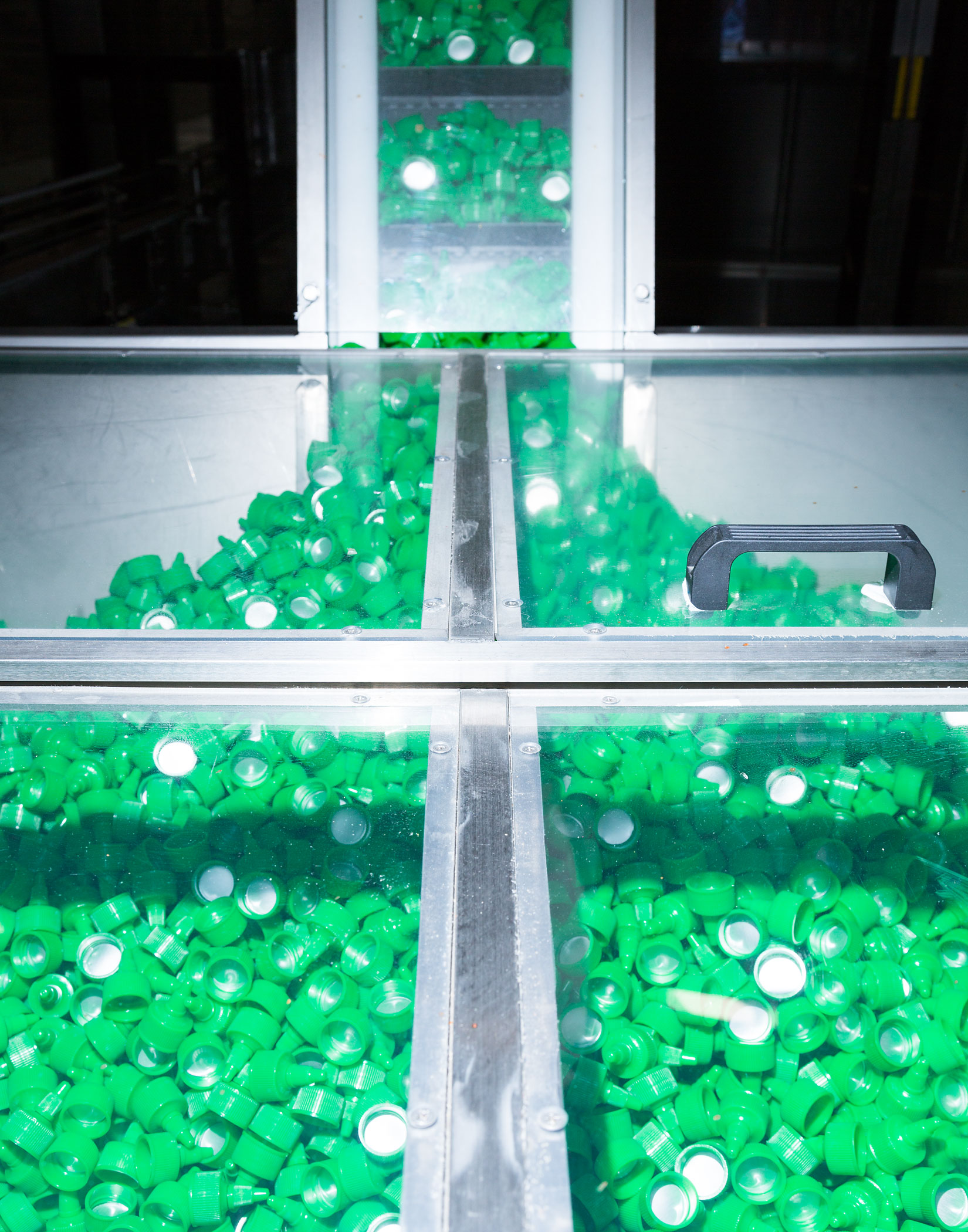

Photos: An Inside Look at a Sriracha Factory

More Must-Reads from TIME

- Breaking Down the 2024 Election Calendar

- How Nayib Bukele’s ‘Iron Fist’ Has Transformed El Salvador

- What if Ultra-Processed Foods Aren’t as Bad as You Think?

- How Ukraine Beat Russia in the Battle of the Black Sea

- Long COVID Looks Different in Kids

- How Project 2025 Would Jeopardize Americans’ Health

- What a $129 Frying Pan Says About America’s Eating Habits

- The 32 Most Anticipated Books of Fall 2024

Write to Olivia B. Waxman at olivia.waxman@time.com