This post is in partnership with Fortune, which offers the latest business and finance news. Read the article below originally published at Fortune.com.

In the technology industry, every new product or service seems to come with the promise that it is an innovation with the potential to change the world. Graphene, a form of carbon, might actually do just that.

“Graphene is a wonderful material,” Jeanie Lau, a professor of physics at the University of California at Riverside, told Fortune. “It conducts heat 10 times better than copper and electricity 100 times better than silicon, is transparent like plastic, extremely lightweight, extremely strong, yet flexible and elastic. In the past decade, it has taken the scientific and technology communities by storm, and has become the most promising electronic material to supplement or replace silicon.”

Graphene has already found its way into a number of compelling applications, Lau said. For instance, “since it is both transparent and electrically conductive — two attributes rarely found in the same material in nature — it has tremendous potential as the transparent electrode in monitors, displays, solar cells, and touch screens,” she explained. “Companies such as Samsung that invest heavily in this area have already secured patents, produced prototypes, and are expected to bring products to market in a few years.”

Wearable electronic devices, aviation components, broadband photodetectors, radiation-resistant coatings, sensors, and energy storage are among numerous other areas of active research, Lau said.

For many researchers and investors, the ultimate application is graphene-based transistors, the building blocks of modern electronics. But getting there may take some time.

A child of graphite

First produced in a lab back in 2004, graphene is essentially a single layer of pure carbon atoms bonded together in a honeycomb lattice so thin it’s actually considered two-dimensional.

“We generally regard anything less than 10 layers of graphene as graphene; otherwise, it’s graphite,” said Aravind Vijayaraghavan, a lecturer in nanomaterials at the University of Manchester.

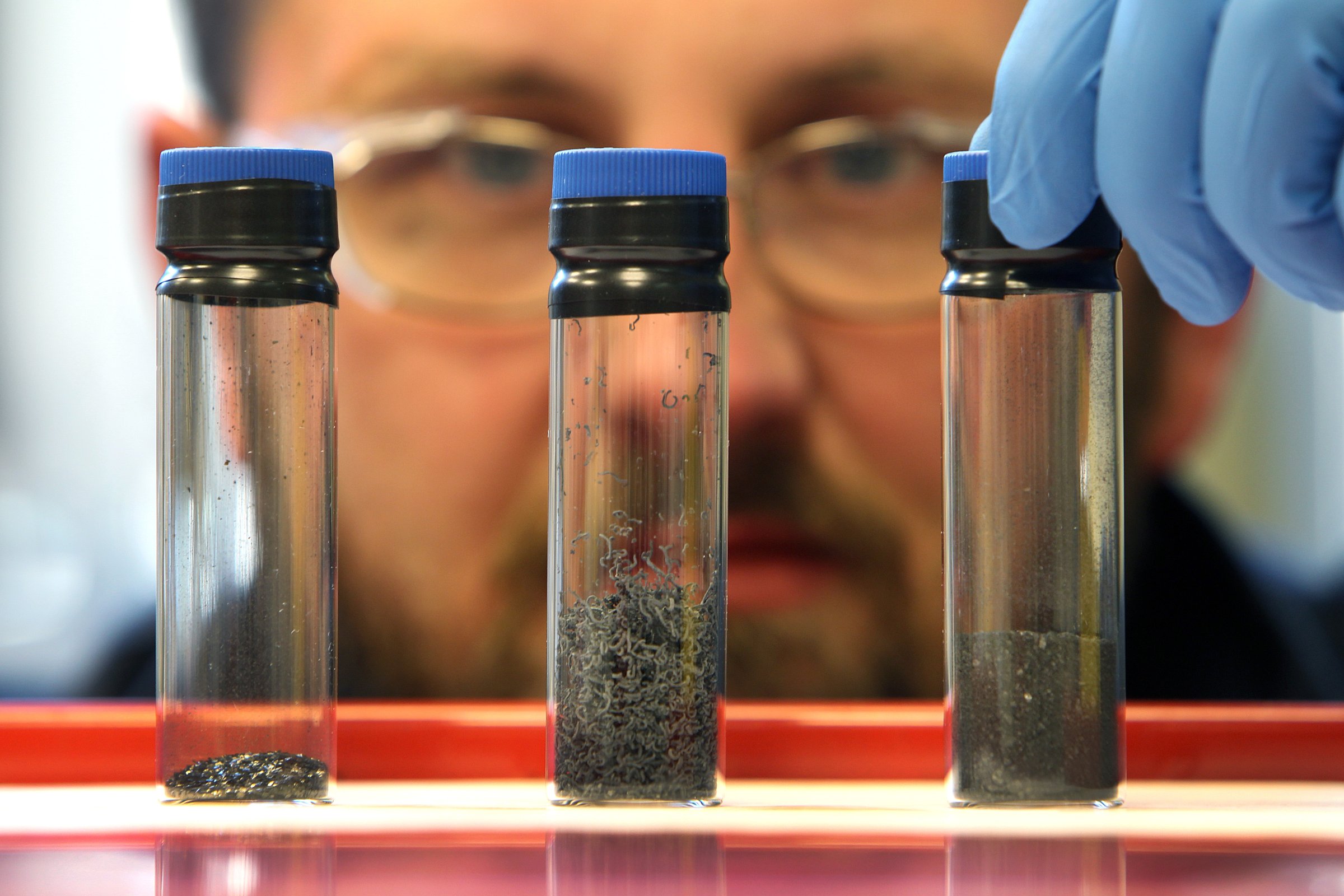

Even “graphene” is a bit of an umbrella term. “To oversimplify, there are two major types of graphene,” Michael Patterson, CEO of Graphene Frontiers, said. The first: “Nanoplatelets,” which are powders or flakes made from graphite. These have been around for a while and are “not really super-sexy,” Patterson said. “You mix them into polymers or inks or rubbers to make them conductive.” In flake form, graphene is already on its way to becoming a commodity, Patterson added.

MORE: Fitness trackers are on the outs, but wearables are not

The other type — in sheet or film form — is where graphene’s biggest promise lies. Graphene sheets have “incredible potential for electronics,” Patterson said. In the near term, that potential may manifest in situations where the quantity requirements are “not that great” and where quality or conductivity doesn’t have to be as high, such as in basic touch-screen applications, he said. Products that use graphene in this way could arrive to market in the next six to 12 months.

Looking a little further out, graphene can be employed in membranes used for water desalination. Lockheed-Martin already has a patented product known as Perforene. “It’s real and it works, but it won’t be economically viable until the product reaches an industrial scale where the cost is measured in pennies per square inch” rather than dollars or tens of dollars per square inch, Patterson explained. “That’s where we’re working today.”

‘It’s expensive and low-capacity’

But use of graphene in semiconductors — the technology’s Holy Grail — is likely a decade away.

“Many of the challenges presented by graphene are common to most new materials,” Paul Smith, a patent associate with the Intellectual Property Law Group at Fenwick & West, toldFortune. “The trick is figuring out how to synthesize graphene in a way that first is manufacturable beyond lab scale; second, preserves the desirable properties of the material; and third, can be integrated into a product or technology.”

Synthesizing graphene in sheet form is considerably more expensive and time-consuming than producing graphene flakes. Whereas the latter typically involves a “quick and dirty” process by which bulk graphite is disassembled into millions of tiny pieces, Lau explained, large sheets of graphene are carefully “grown” on substrates such as copper, germanium, or silicon carbide.

MORE: Personal digital assistants, rise up!

Graphene sheets are also prone to defects and “very difficult to make in good quality,” Ron Mertens, owner and editor of Graphene-Info.com, said.

Production capacity is also very limited. “There are thousands of small companies that can make graphene, but it’s expensive and low-capacity,” Mertens said. A round wafer measuring one inch in diameter, for instance, costs about $100, he added.

An even thornier obstacle on the way to graphene transistors is the fact that the material has no “band gap,” an essential property that allows transistors to be turned on and off without leaking electronic charge in the “off” state, said Elias Towe, a professor of electrical and computer engineering at Carnegie Mellon University.

“Band-gap engineering has been and remains the biggest challenge in the development of graphene transistors and computer chips,” Lau said.

It requires controlling the material almost down at the atomic level, and “that’s really pushing the edges of existing technology,” Patterson said. “In 10 years, we’ll start to see these problems be solved.”

‘It is largely a matter of time’

If graphene is to succeed as a replacement for silicon, every unit of cost and performance will make a difference, Towe said.

“Silicon is hard to displace, with all the billions dollars of investments made in manufacturing infrastructure,” he said. “A replacement for silicon has to offer extraordinary performance at extremely rock-bottom cost to compel industry to change its way.”

Though graphene is just 10 years old — in contrast, use of silicon in transistors dates to the early 1950s — considerable progress has already been made. For example, the largest graphene sheet was produced by hand in a laboratory eight years ago; its width was less than that of a human hair. “Nowadays, roll-to-roll printing of graphene sheets up to 100 meters long has been achieved,” Lau said.

“With the increasing interest, investment, and research in graphene-based technology, I think it is largely a matter of time before the economy of scale kicks in and truly low-cost, large-scale production of high-quality graphene is accomplished,” she added.

MORE: Why Google and Facebook are drooling over drone companies

The next series of hurdles “can be overcome with time and effort,” said Vijayaraghavan of the University of Manchester. “We’re learning new things every day. There is still much we don’t understand, and still plenty of research to be done.” For example, researchers have only just begun to study the consequences of graphene pollution on the environment and human health.

Still, the possibilities that graphene holds for the nearly $2 trillion global electronics industry are difficult to ignore.

“Imagine a tiny chip, one-tenth the size of a postage stamp, that your doctor could use to test for all kinds of things,” Patterson said. “You’d walk in, and instead of having to give three vials of blood to test for two things and then get the results the next day, your doctor could use one drop of blood to test for hundreds of things and you’d get the results right away. Graphene makes it possible.”

More Must-Reads from TIME

- Cybersecurity Experts Are Sounding the Alarm on DOGE

- Meet the 2025 Women of the Year

- The Harsh Truth About Disability Inclusion

- Why Do More Young Adults Have Cancer?

- Colman Domingo Leads With Radical Love

- How to Get Better at Doing Things Alone

- Michelle Zauner Stares Down the Darkness

Contact us at letters@time.com