In the predawn darkness of the western Mojave Desert, workers make their way across a parking lot toward a sprawling complex of factories, hangars and runways. Teams of armed military and civilian guards patrol the grounds leading to the 5,800-acre facility, which is ringed by an elaborate security system and monitored from space by orbiting reconnaissance satellites.

At a fence bristling with razor-wire, the men and women pull key cards from their belt-loop lanyards, flash them on a contact sensor, punch in their numerical codes and push through high-gate turnstiles. Inside, they stow signal-emitting electronics like iPhones and earbuds at a bank of storage shelves, then swipe in at computer monitors to confirm their identities and security clearance. At last, they step onto a gleaming production floor the size of several football fields, a place off-limits to anyone who doesn’t have authorization to the “black world” of U.S. government secrecy known as SAR: Special Access Required.

This is U.S. Air Force Plant 42, where the military’s new stealth bomber, the B-21 Raider, is built. After nearly a decade in the shadows, the B-21 was presented on Dec. 2 evening to an invitation-only crowd of 3,000, including Defense Secretary Lloyd Austin, top military generals, industry executives and factory workers. The thin gray aircraft resembled a stingray as it glided through the parting hangar doors and artificial fog to applauding visitors, who were stationed 75 feet away and only permitted to view it head-on to maintain a veil of secrecy. Later, Austin spoke about the B-21’s ability to carry “nuclear and conventional munitions” along with future weapons not yet invented. “We are again making it plain to any potential foe: the risks and costs of aggression far outweigh any conceivable gains,” he said.

The B-21 is America’s first advanced weapon system in a new Cold War with Russia and China. Strategists at the Pentagon envision the radar-evading B-21 penetrating those countries’ air defenses to strike fortified targets should the growing military competition with Moscow and Beijing ever turn hot. If everything goes to plan, aerospace giant Northrop Grumman Corp. will produce at least 100 B-21s for the Air Force in the coming years at a current cost of $692 million per bomber—a price tag comparable to that of a skyscraper.

But the road from well-funded Pentagon war plans to deployable high-tech weaponry is littered with expensive failures. For nearly 40 years, the Air Force has been unable to purchase new planes on time, on budget, and in sufficient numbers. The last time the Air Force bought a bomber, in the 1980s, it wanted 132 planes at about $500 million per aircraft. What it received was 21 bombers at $2 billion apiece. Northrop was its partner on that project too and stumbled through production delays and engineering snags. The B-21’s predecessor, known as the B-2 and produced at the same facility, became a symbol of the government’s broken procurement process—a cutting-edge weapons system that is high-priced, short in supply, and seldom used.

The question hanging over the B-21 is whether Northrop and the Air Force have learned their lessons from the past before embarking on this new, massive, strategic gamble. For the past year, TIME has followed the development of the B-21, visiting Plant 42 ahead of the rollout, observing engineering, manufacturing and testing teams; speaking with more than three dozen military, industry and political personnel involved with the program; and reviewing government documents detailing costs and development. While the program has hit early milestones, the largest challenges lie ahead for the Pentagon and its tendency to underestimate risk, technical difficulty and cost to get big-ticket programs like B-21 rolling.

More than money is at stake. Success or failure for the B-21 program may determine whether the U.S. retains a long-range bomber advantage over its global rivals or saddles taxpayers with interest payments on yet another gold-plated budget-buster for years to come.

Each B-21 bomber begins its life on the northern end of Building 401 at Plant 42 as a wedge-shaped, granite-colored shell of light-weight composite materials. It moves southward down the line from one workstation to the next, transforming into a bomber: avionics, radars, sensors, weapons bays, windows, and wings. Traditionally, airplanes are manufactured from the inside-out, but it’s the other way around for stealth craft. Hundreds of thousands of parts are pieced together inside the B-21’s sleek boomerang-shaped shell. The goal is to keep the sinister-looking jet’s exterior as smooth as glass to reduce radar-reflection.

Stealth is the B-21’s defining feature. From the beginning, Northrop’s engineers have labored to create a plane that can fly undetected through enemy air space and remain invisible to missiles and fighter jets. To lower the infrared and acoustic “signatures,” the B-21 is designed to fly at subsonic speeds, powered by jet engines embedded into the wings like shark gills. High-tech coating materials are applied to the rounded exterior, creating a sponge-like skin reputed to absorb radar waves as they strike the aircraft. The B-21 is designed to be even stealthier than the B-2, which reportedly appeared no bigger than a tennis ball on radar screens despite a wingspan akin to a 747 jumbo jet.

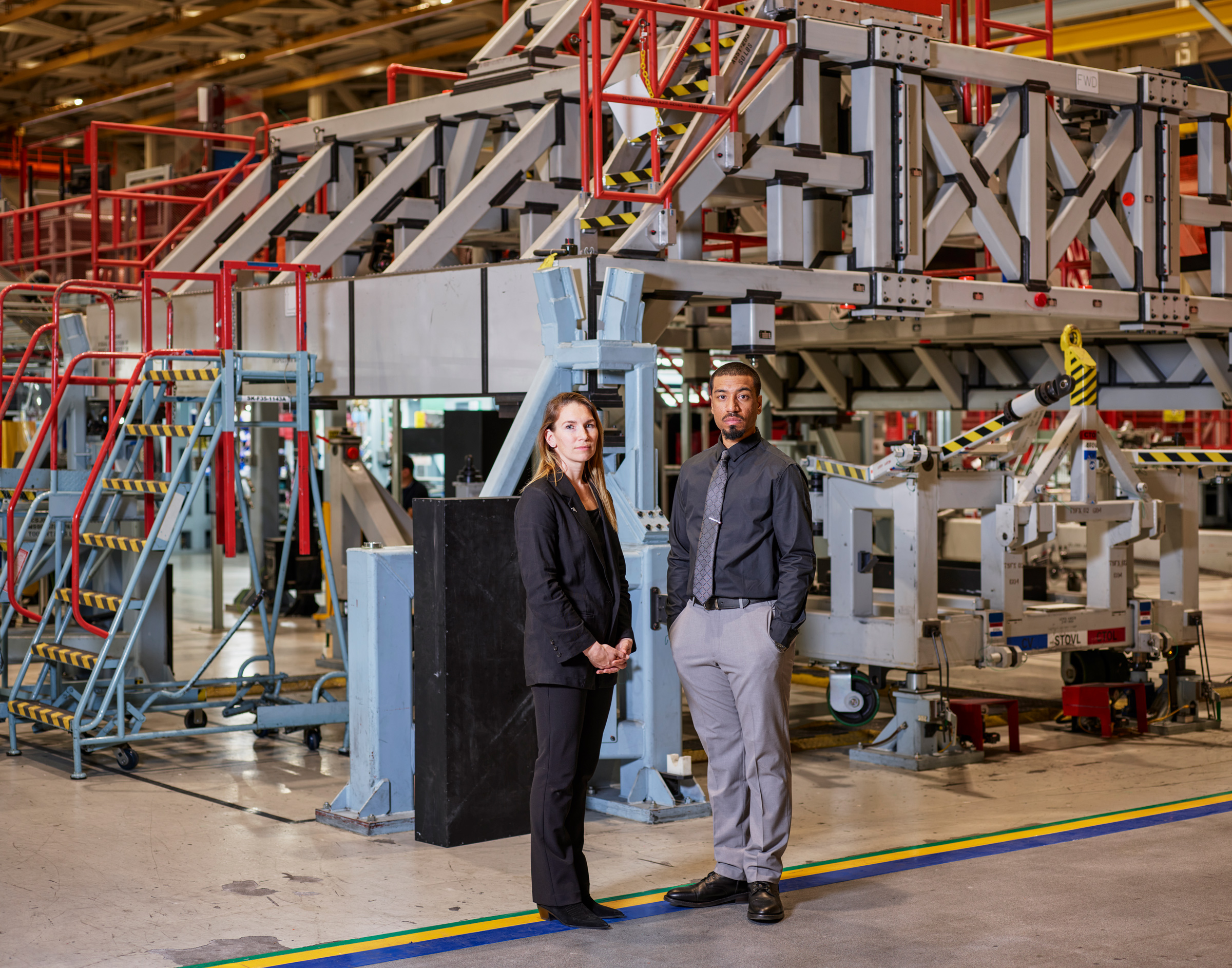

The B-21’s size, weight, range and payload remain undisclosed, but to the trained-eye it’s noticeably smaller than the B-2. Many of the plane’s technical details, however, will likely remain classified for as long as any of us are alive. The Air Force and Northrop have poured an untold fortune to prevent information from leaking out. Many suppliers remain unaware they are making parts for the B-21. Northrop engineers and technicians were unable to tell family or friends they worked on the program until June and even then, couldn’t reveal details about what they do all day. “There can be some challenges because we can’t really talk about what we do at work,” says Hassan Charles, a B-21 technician at Plant 42. “But a lot of hands went into making this bird, a lot of hours, a lot of challenging times.”

One Tuesday in November, Charles and dozens of workers swarmed around four unfinished B-21s, tinkering with fasteners, gauges, switches, and wiring designed to withstand a nuclear blast. It’s hand-on, labor-intensive work carried out by technicians rather than robots on an automated line. The B-21 team has churned out two planes thus far: T-1, the aircraft unveiled during the Dec. 2 rollout, and G-1, which is now undergoing ground tests. Since winning the bomber contract in October 2015, Northrop has constructed three new buildings for assembly here at Plant 42, renovated workspaces and has jump-started new hiring programs to add to the 5,000 people now employed on the program. When new employees are hired, they often wait weeks until they obtain government clearances, an investigation process to weed out potential spies and criminals.

Read More: The Mission to Modernize America’s Aging Nuclear Missiles.

Perched above the assembly line is a strip of offices, where Northrop’s B-21 engineers work. The maze of gray cubicles is festooned with artwork scotch-taped to the walls, featuring grinning skulls and pirate-themed posters with phrases like, “Rise of the Raider.” (The B-21’s nickname, Raider, was inspired by the improbable 1942 U.S. air raid on Tokyo during World War II led by Lieutenant Colonel Jimmy Doolittle.) The team uses the latest virtual modeling and three-dimensional simulation programs to identify and eliminate technical issues before they physically get onto the jet. The company says the digital approach should help cut time and cost as the program nears flight-testing.

Embedded with the Northrop team is Colonel Tim Spaulding, the Air Force’s B-21 program director and certified test pilot. Spaulding says he is confident the technology is flagging some flaws. But tempering expectations, he says unforeseen issues inevitably will be discovered when the plane first takes to the skies next year. “It’d be great if you didn’t have to learn anything when we build a complex project,” Spaulding says. “We know we will. Our goal is to learn it as quickly as we can and to be able to make whatever corrections, if any are required, as quickly as we can.”

As much as anyone, Spaulding is responsible for keeping the program on time and on budget. More than once, he’s had to balance the urge to add new capabilities to the plane with the fear of getting derailed from the schedule. He’s aware of the cascade of mistakes that have long-plagued Air Force projects: ever-changing design requirements, unreliable production rates and exploding cost projections. “Everyone wants a Battlestar Galactica, packed with the latest technology,” he says, driving between buildings at Plant 42. “We have to get the first airplanes out there and going, before we’re ready to make them better.”

So far, the Air Force says, the B-21 is hitting all its projected targets, but it’s hard to independently discern the plane’s true costs. Yes, the bomber’s projected $692 million per plane price tag is below the planned costs that the Pentagon announced a decade ago. But the unclassified numbers—published under the Air Force’s procurement and “Research, Development, Test and Evaluation” budget lines—don’t tell the whole story. Huge swathes of the program remain classified and if it garners so-called “black budget” funding, the public won’t know. According to the Pentagon’s 2023 request, the Air Force plans to spend nearly $20 billion on producing the B-21 for the next five years, but it’s not clear how many planes that will buy. Production timelines and rates are classified.

Secrecy is a means to keep foreign adversaries in the dark, but it’s also a means to hide costs, says Chuck Spinney, a retired Pentagon weapons analyst who has spent more than a half-century studying politicization of defense procurement. “The trouble with maintaining oversight on programs like the B-21 is all the interesting parts are black,” he says. “That’s by design. It’s business as usual. Because when we find out that something goes wrong—and something always does—it’s either too early to tell or too late to do anything about it.”

More expenditures lie ahead. For instance, the B-21 is designed to drop nuclear weapons, requiring special testing and equipment. But the Air Force doesn’t intend to certify the plane for nuclear missions until two years after it enters service sometime in “the mid-2020s,” according to Pentagon auditing documents. Outside analysts view that as a cost-cloaking decision that defers requests for additional funding into future budgets. In addition, the B-21 is designed to be one part of a “family of systems,” which may include drones flying alongside it on future bombing runs. It’s not clear if additional funding will be needed for the system to function properly together.

Such financial oversight evasion is an area of long-standing expertise for the military, says William Hartung, senior fellow with the Quincy Institute for Responsible Government. “The Pentagon routinely understates the costs of major systems, and I expect the B-21 to be no different,” he says. “It’s not a question of whether there will be overruns, but how high they will go, and whether they lead to massive additional spending or a reduction in the proposed buy of the planes.”

The Pentagon’s most recent fighter-jet program, the F-35, has been beset with production delays and cost overruns for 21 years, with acquisition costs nearly doubling to $428 billion for 2,470 planes. Before that, the Air Force wanted 648 F-22 fighter jets for $149 million each. It received 188 at a price tag of more than $400 million per copy. With this track record, says William LaPlante, the Pentagon’s chief weapons buyer, the suspicion of the B-21’s true costs is understandable. “Since the beginning of the program, there’s always been a lot of skepticism—and I think for good reason,” he says. “We’re just going to have to keep proving to the American people and hold our military accountable to the fact that the program is going well.”

The aerospace industry was stunned when underdog Northrop won the B-21 contract in 2015, beating out a joint-bid by the nation’s two largest defense contractors, Boeing Co. and Lockheed Martin Corp. Northrop’s work on the B-2 had changed the fortunes of the company from a small firm known for building lightweight fighters into a defense behemoth. But even though Congress invested more than $20 billion in research and development for the B-2, the bat-winged bomber turned out to be a delicate creature. Its radar-evading qualities were revolutionary in military technology, but it turned out those same features demanded constant coddling and were sensitive to everything but picture-perfect weather. The B-2 is derisively called a “hangar queen” because for each hour one is in the air, it spends 51 hours on the ground in maintenance, according to Air Force statistics. The jet has made more appearances flying over air shows and sporting events than it has above active battlefields. For every hour it’s airborne, it costs $150,741, the Government Accountability Office reported in November.

Northrop contends stealth technology has come a long way since the B-2 when many aerospace engineers still used slide rules and drafting tables. A small number of employees on the B-21 worked on its predecessor, themselves, and a cadre of retired engineers are called upon for advice on avoiding pitfalls. The battle-scars of the B-2 may help alleviate the problems Northrop ran into on the first project. “When I walked in the door, very early days, I was handed a B-2 lessons-learned paper, and was pretty much told to memorize it,” says Jessi Ross, a B-21 director at Northrop. “And it covered everything, as far as successes and things we would like to do better if we had an opportunity to go do it again.”

While the B-2 needs a specialized temperature-controlled hangar, Northrop engineers say the B-21 will be left outside under a shelter along the flight line like other planes. Where mechanics spend hours scraping away radar-absorbing material on the B-2 to access wiring under its 100-plus panels, the plan is for those doors to simply pop open on the B-21. And while it can require months of maintenance for a B-2 to fly, the B-21 is designed to do so every day.

The B-21 is a prospective gold mine for Northrop, whose annual revenues have soared 52% to $35.7 billion in the seven years since being awarded the initial contract. Air Force officials say that over the next 30 years it will cost at least $203 billion to develop, purchase and operate 100 B-21s. And Northrop hopes the Air Force will order far more. For that to happen, the jets need to move out of assembly and into the hands of Air Force pilots, says Kathy Warden, the company’s chief executive officer. “It’s constantly in our mind that we have an obligation to deliver on our commitments,” Warden tells TIME at Northrop’s headquarters in Falls Church, Va. “Part of that is the affordability commitment that we make, not just the technical capability that we’re delivering. And that proved to be a challenge for the Northrop Grumman team on the B-2.”

Read More: Chinese and Russian Warplanes Patrol the Pacific In a Show of Strengthening Military Ties.

In April, Warden announced Northrop received a $67 million incentive fee from the Air Force for hitting performance targets thus far. The company plans to continue to stay ahead of timelines in the coming months. Typically, the first assembled jets are one-off prototypes that need to be heavily modified once the design kinks are worked out. The B-21 rolled out Dec. 2 is more or less production-ready, Northrop officials say, which they hope will streamline the testing process.

Veteran budget watchers remain skeptical. “The reality is the cost of high-tech systems invariably rises because of unrealistic goals and impractical solutions,” says Dan Grazier, a retired Marine captain with the nonprofit Project On Government Oversight. “We shouldn’t act surprised if the B-21 doesn’t live up to every promise.”

Theoretically, the end of a major war like the one in Afghanistan brings a “peace dividend,” with curtailed defense spending. Not so this time in the unruly wake of the U.S. retreat from Kabul in August 2021. In October, the Biden Administration unveiled a new defense strategy that puts the U.S. military on a Cold War-footing with both Russia and China. The plan foresees the U.S. confronting two nuclear peer-adversaries for the first time in history with a multi-year build-up of modernized weaponry, enhanced foreign alliances and a top-to bottom $1.2 trillion overhaul of the American nuclear arsenal.

The B-21 is a significant line-item in that national security plan and, its designers hope, an important part of America’s ability to project force around the world. Onboard computers allow the bomber to fly with a pilot or as a drone, and will enable it to share data with other airborne warplanes. It will also use an open-architecture design, so capabilities are updated and improved with software upgrades rather than hands-on maintenance overhauls.

It’s not hard to see why planners want the new plane. The Air Force now has the smallest and oldest fleet in the nation’s history. Roughly half of the Air Force’s 141 bombers are B-52s, which rolled off assembly lines during the Kennedy Administration. During the last Cold War, the military’s justification for big weapons programs focused on the Soviet Union, but the argument has shifted today as tensions with China rise. In the Asia-Pacific region, extensive distances are an obstacle for any battle plan, and Beijing has spent years investing in its air defense network with sophisticated radars, long-range S-400 surface-to-air missiles, and J-20 stealth fighters. These systems could prove problematic if, for example, China decides to invade the U.S.-allied island of Taiwan and an American President chooses to help defend it. Salvos of cruise missiles could slam into many targets from more than 1,000 miles away, but only a bomber can persist in contested airspace, find, identify, and attack mobile missiles threatening U.S. aircraft carriers and other forces.

The new B-21 stealth bombers are designed to fly thousands of miles away, slip undetected through enemy air defenses, drop several tons of bombs on targets and clear the way for U.S. and allied militaries. Only the B-2 can currently do that, and the U.S. owns just a handful.

That’s one reason the B-21 appears to have budgeting tailwinds behind it. Another is bipartisan support for the program that has been generated in part through concerted lobbying. Northrop spent $8.7 million in 2022 on lobbying, according to OpenSecrets.org. Among the talking points: the fact that the B-21 now provides 8,000 jobs in 40 states with the promise of more if production ramps up.

Now that the bomber has been unveiled, the next challenge will take place about 25 miles northeast of Plant 42 at Edwards Air Force Base. There, high above the desert, test pilots will push the jet to its aerodynamic limits. How it performs will go a long way to revealing whether the stealthy B-21 program—or just its costs—are primed to take off.

With reporting by Anisha Kohli and Julia Zorthian

More Must-Reads from TIME

- How Donald Trump Won

- The Best Inventions of 2024

- Why Sleep Is the Key to Living Longer

- Robert Zemeckis Just Wants to Move You

- How to Break 8 Toxic Communication Habits

- Nicola Coughlan Bet on Herself—And Won

- Why Vinegar Is So Good for You

- Meet TIME's Newest Class of Next Generation Leaders

Write to W.J. Hennigan/Palmdale, Calif. at william.hennigan@time.com