For a long time, I couldn’t even bring myself to tell people that I was an inventor. If they asked me what I did, I’d always answer, “I’m the mother of three children.”

The success of the Miracle Mop changed my life. It was the beginning of my rebirth into a more confident, creative person. It allowed me to trust my instincts even more. My confidence in my ideas and my vision grew and grew. You know how, if you saw a friend walking with bare feet over sharp little rocks, you’d feel very certain in concluding that they needed to put on shoes? Well, that’s how sure I was becoming about my ideas for new products and new creations — as if it was obvious that they needed to exist. I went to all kinds of stores, attended trade shows and tried to keep my eyes open for new inspiration.

At one event, I noticed an item by a company from Holland. It was a little roll-up storage kit you could use for organizing knickknacks. You rolled it out to see everything in its respective compartment, and you rolled it back up to store it away. In an instant, it hit me. Two simple words: Junk drawer.

Everyone has a junk drawer. You know, the drawer where you throw everything that has nowhere else to go. Pens, pencils, batteries, beads, ribbons, spools of thread, Band-Aids, Matchbox cars, anything. And when you open it up, everything jangles and clangs around and you can’t find the one thing you absolutely must find at that very moment. But what if everything we keep in our junk drawers could be rolled up and tucked neatly away in one place? Not in a bag that could topple and spill over, or a drawer that could be pulled out too far and scatter a million tiny items under the sofa. No — a sturdy rolling kit that could be put away safe, snug and secure.

I took the idea to QVC, and they gave me the go-ahead. I contacted the patent holders in Holland, and we signed a deal to remake the kits based on my improvements to their design, using the same plastic we used for the Miracle Mop. They sent us their molds, and at my new warehouse we set up more assembly tables right next to the ones we used to make the mops. Then we got to work, and the Rolykit was born.

Right away, people got it. They saw the same thing I did in my mind. I guess I wasn’t the only one with a junk drawer problem. The Rolykit became one of QVC’s best-selling products. It sold out pretty much every time I went on the air with it. I made a second Rolykit designed for children in bright colors, and called it the RolyPoly Kit, because that’s what my kids children called it. As the months and years passed, the Rolykit just kept going. The orders got bigger and bigger.

So I decided to create a brand-new product using the same roll-up design — a beautiful, luxurious, multi-compartment jewelry box. Jewelry clutter was another problem I knew too well. Keeping rings and chains and bracelets separate and organized was almost impossible. How many times did I have to untangle two necklaces that didn’t want to come apart? But what if I could design a small box that featured elegant, velvety trays, like the ones they have in fancy department stores, but that also rolled up and allowed you to keep your necklaces away from each other and your rings and bracelets from getting all jumbled up?

The prototype we created was stunning. The smooth exterior was a shiny black, and when you opened the top you saw a deep compartment covered with a rich, dark velvety fabric, and a mirror that flipped to just the right angle. There were little slots on one side of it where you could arrange your rings and keep them separate. When you unrolled each side, there were more deep, velvety trays. Every piece of jewelry you stored in this box would fit snugly into its own protected space.

I took the prototype to QVC, and they loved it, especially Jeff Taraschi, who at the time was running QVC’s booming jewelry division. Jeff was brilliant and energetic and contagiously positive, as well as aggressive and confident in his instincts. He put in an order for 50,000 Jewel Kits. That left me with around six months to create, box and ship 50,000 units — a pretty tight schedule, but not impossible as long as everything went smoothly.

Everything did not go smoothly.

The biggest challenge was the velvety trays. They had to be created through a process called flocking. Flocking a flat surface was easy, but our trays weren’t flat, they were sunken and rounded. Nothing we tried worked right. Several times I had to fly to Wisconsin, where the trays were being made, to inspect the progress. Each time I’d meet the engineers at the airport, look at the trays, point out all the problems, then get right back on a plane to New York. Two months passed — a third of the way through our production schedule — and we still hadn’t manufactured a single tray.

Around then, I got a call from Jeff Taraschi. “Joy!” he said. “How’s it going?”

“Great!” I answered. “It’s going great!”

“You’ll make the deadline, right?”

“Of course we will!”

“Okay! Go get ’em!”

I flew to Wisconsin again, this time to visit the factory. There, I found two workers assembling just 10 trays. I had to deliver 50,000 Jewel Kits in three months.

I finally switched to a new facility. I flew to the new plant in Wisconsin and laid down the law. “Guys, we have to start manufacturing these kits right now,” I told the workers there. “Let’s roll up our sleeves and work out a schedule and stick to it.” Right away, one of the workers told me the plant would be closed the following week. Not for a day or two — for the whole week. “Sorry,” he said. “It’s hunting season.”

In the end, we were only able to ship 25,000 Jewel Kits to QVC in time for the first show. Only half the order. That wasn’t a just minor inconvenience — it was a major problem. In the product business, you simply have to have enough units to sell, and half orders just don’t cut it. When I finally went on the air to talk about the Jewel Kit, we sold all 25,000 kits the very first morning. Jeff was right — we could have easily sold the full 50,000, and then some.

After the Jewel Kit, I just kept going. I created a bucket for the Miracle Mop that held it upright with its handle, so the mop wouldn’t scrape your wall when you dropped it (the Tuck-it Bucket). I made a travel mirror with a built-in, flexible arm, so you could unwind it anywhere (the Handy Hook Mirror). And I came up with the Piatto Bakery Box while having ice cream with my children.

And yet, the success of my products did not change the basic reality of my life — that every new product I created had to be successful, or else I’d be out of business. The nature of what I was doing required me to put so much money into creating the products that if any of them didn’t sell well, I’d be in deep financial trouble. I had no margin for error.

Every decision I made was make-or-break — and yet all I could do was trust myself as an inventor. Always listen to the experts, people told me again and again. The experts know what they’re doing. Just listen and learn, and you’ll be fine. Well, that’s simply not true, because there are no experts. There are only people with great ideas. And great ideas can come from anyone. Including you.

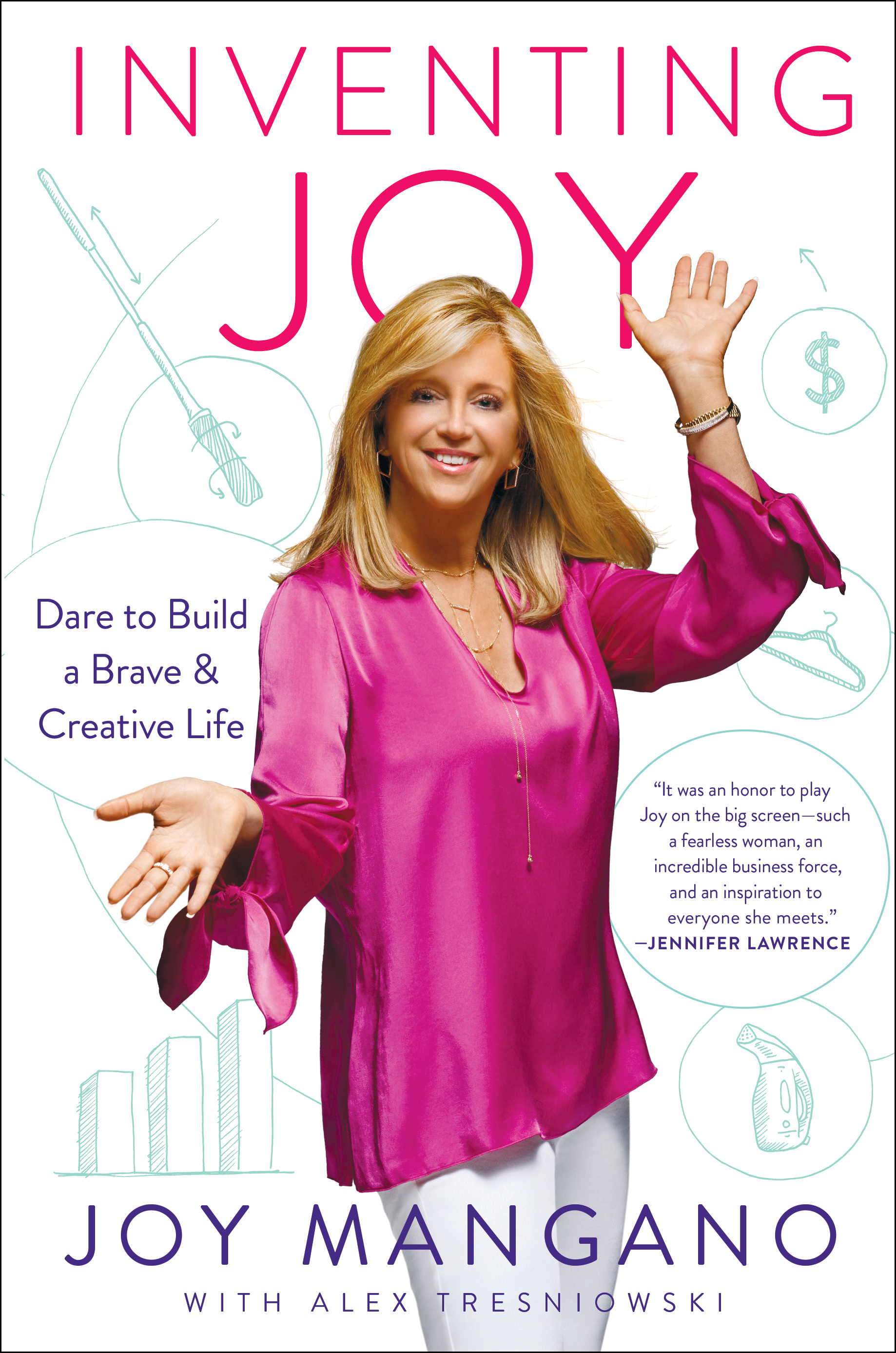

Copyright © 2017 by Joy Mangano. From the book INVENTING JOY by Joy Mangano, published by Simon & Schuster, Inc. Printed by permission.

More Must-Reads from TIME

- Cybersecurity Experts Are Sounding the Alarm on DOGE

- Meet the 2025 Women of the Year

- The Harsh Truth About Disability Inclusion

- Why Do More Young Adults Have Cancer?

- Colman Domingo Leads With Radical Love

- How to Get Better at Doing Things Alone

- Michelle Zauner Stares Down the Darkness

Contact us at letters@time.com