There’s a new robot in town.

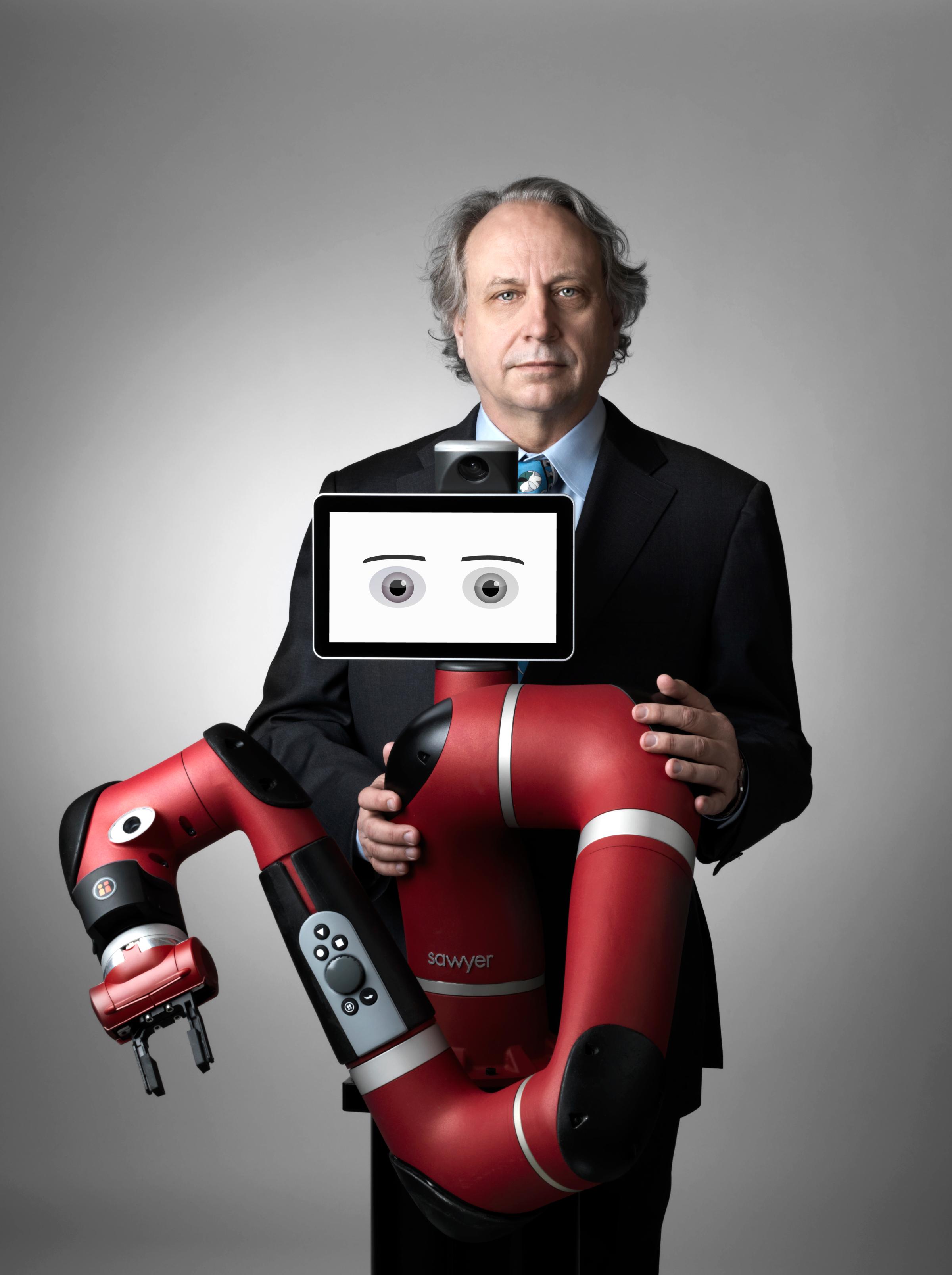

Meet Sawyer, a new robot unveiled Thursday by Rethink Robotics, a Boston-based robotics company aiming to make factories more efficient, safer and more productive.

Weighing in at 41.9 lbs and standing 3.3 feet tall, the one-armed Sawyer is smaller and more flexible than Rethink’s only other robot, the double-armed Baxter, which debuted in 2012. While Baxter has helped companies do heavy duty work like loading boxes, Sawyer was created to automate more detailed, smaller tasks, like testing circuit boards and machine tending — jobs that have traditionally proven too intricate for industrial robots.

“[Baxter] gave us a tremendous base of companies that were thinking like us. We have a vision, idea and experience, but we don’t necessarily have all the answers,'” Rethink CMO Jim Lawton says of Sawyer’s development, which began in late 2013. “It’s like taking one step across the river. You can’t get there in one step, so you need to build commercially viable products as stepping stones. Eventually, you get to the other side of the river.”

Rethink’s customers have already used both robots — though Sawyer only in field tests — to perform low-level factory jobs, positions that are often menial, dangerous or undesirable. The machines are also relatively cheap: Sawyer will start at $29,000 when it’s introduced more widely this fall, while Baxter starts at $25,000; similar robots can cost several times more. The robots’ signature touch is digital “faces” that double as easy-to-use interfaces, allowing companies to get Sawyer and Baxter up-and-running within hours or days.

Together, Sawyer and Baxter are just two of the many robots fueling fears automation and other technologies are taking humans’ jobs. Rethink is used to the criticism: factory labor has long been a politically charged topic, and the seven-year-old startup has often been in the spotlight thanks to its big-name investors like Bezos Expeditions and Charles River Ventures. Rethink’s most recent funding round in January raised $26.6 million. That’s considered a significant investment in the robotics industry, which is expected to grow 12% globally every year, according to the International Federation of Robotics.

Still, Rethink Robotics argues that its robots will only supplement their human counterparts, not outmode them. “Companies who are buying robots are filling in the tasks they can’t get people to stay and do,” says co-founder Rodney Brooks. “They’re using the people they have more positively by using their intelligence.”

Global manufacturing company Jabil, which uses thousands of robots including Sawyer and Baxter, agrees that robots will support instead of replace manufacturing workers. After all, the manufacturing field is in global decline as emerging and advanced economies shift toward high-skill jobs, according to a McKinsey Global Institute report. In the U.S., for example, the share of jobs in manufacturing fell from 25% in 1950 to about 9% in 2013.

“The trend that’s across the entire manufacturing continuum is a demographic shift that’s making it more and more difficult to attract the kind of low-cost labor that we’ve been able to do in the past, and to keep wages at the levels they’re at,” says John Dulchinos, VP of global automation at Jabil. “Robots by themselves aren’t the answer, but robots are a piece of the equation.”

More Must-Reads from TIME

- Cybersecurity Experts Are Sounding the Alarm on DOGE

- Meet the 2025 Women of the Year

- The Harsh Truth About Disability Inclusion

- Why Do More Young Adults Have Cancer?

- Colman Domingo Leads With Radical Love

- How to Get Better at Doing Things Alone

- Michelle Zauner Stares Down the Darkness

Contact us at letters@time.com