Lawmakers in Irwindale, California dismissed on Wednesday a bill that would have deemed the company behind Sriracha hot sauce a public nuisance. Three Irwindale City Council members and Mayor Mark Breceda unanimously voted to drop the legislation targeting Huy Fong Foods, Reuters reports.

“We have to keep employment in Irwindale. We have to expand. It’s good for Irwindale. It’s good for California,” Breceda said. The factory employs 70 full-time workers, 200 seasonal workers, and pumps out over 20 million bottles of the popular hot sauce every year. Sriracha is made from ground fresh chilis; the factory then uses exhaust fans to suck out the spicy air, filter it through pipes, and expel it through the roof.

Residents of the Los Angeles suburb have long complained about the pungent fumes emerging from the factory, citing headaches and irritated eyes, throats and noses. One resident likened the odor to “pepper spray.” Had the bill passed, Irwindale could have acted on its own to dispel the fumes, with Huy Fong Foods taking on the costs.

“If it doesn’t smell, it doesn’t sell,” said David Tran, founder and CEO of Huy Fong Foods, in October.

[Reuters]

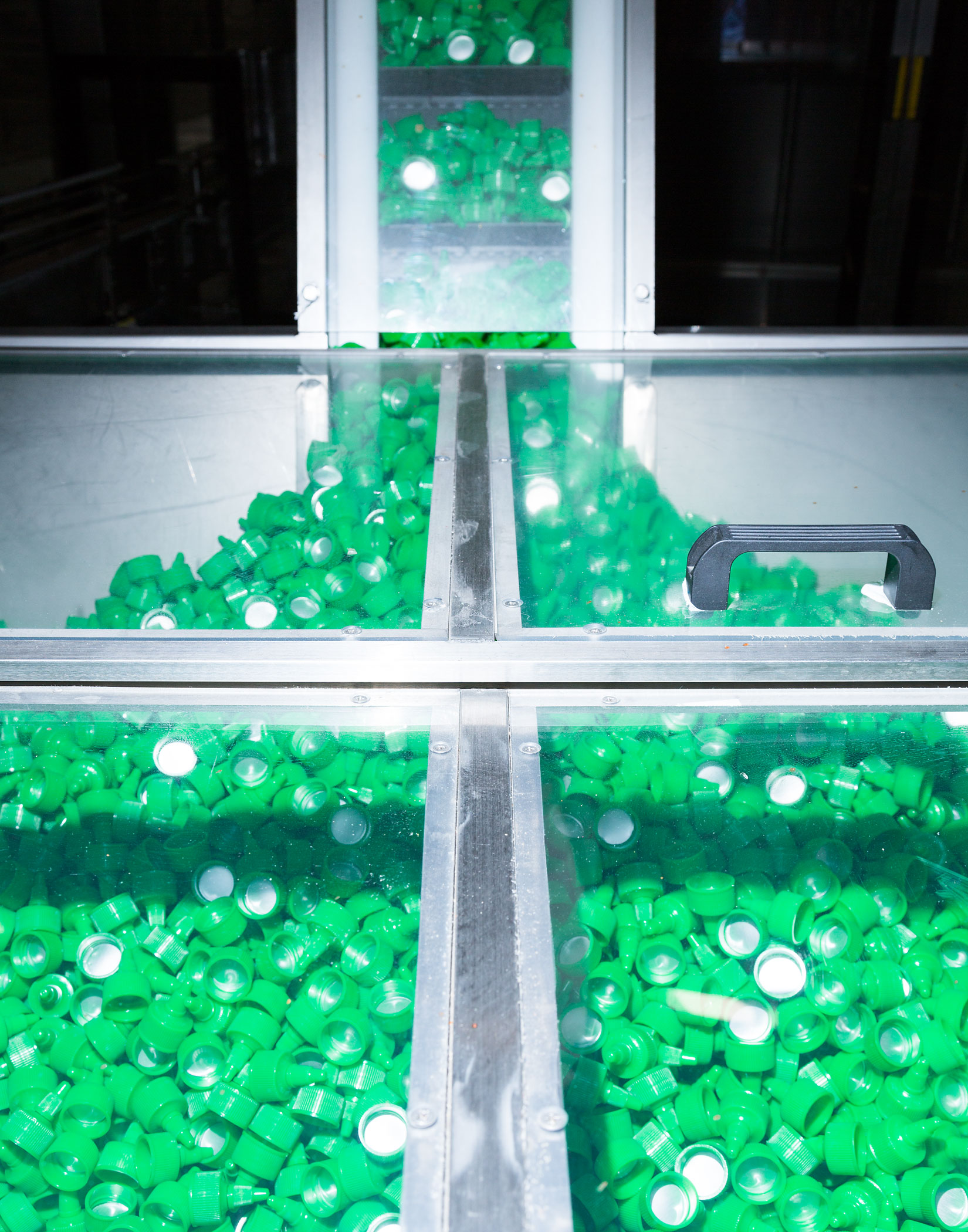

Photos: An Inside Look at a Sriracha Factory

More Must-Reads from TIME

- Why Trump’s Message Worked on Latino Men

- What Trump’s Win Could Mean for Housing

- The 100 Must-Read Books of 2024

- Sleep Doctors Share the 1 Tip That’s Changed Their Lives

- Column: Let’s Bring Back Romance

- What It’s Like to Have Long COVID As a Kid

- FX’s Say Nothing Is the Must-Watch Political Thriller of 2024

- Merle Bombardieri Is Helping People Make the Baby Decision

Contact us at letters@time.com